Plasma treatment of radwaste

BELGOPROCESS offers a proven plasma treatment technology for low- and intermediate level radioactive waste and problematic chemical waste that uses a high-temperature plasma processing technique with operating features that eliminate the personnel exposure and costs associated with sorting, characterizing and handling this waste and gives a final product that meets most stringent acceptance criteria for final disposal.

By means of a plasma torch of about 5000 °C, the inorganic material is melted into a glassy slag containing the radioactive isotopes. The organic material is gasified and subsequently oxidized in an afterburner and purified in an off-gas purification plant. The glassy slag is free from any organic material and liquid/sludge and is very suitable for long-term storage and disposal due to the physico-chemical and mechanical stabilization of the waste.

Because the waste can be processed without pre-treatment – drums can be processed unopened – there is no longer a need for expensive sorting and pre-treatment infrastructure or other treatment installations for non-combustible waste. In addition, direct radiation exposure and contamination risks for staff are minimized.

Plasma technology can also be applied to recondition previously conditioned waste packages that no longer meet the present acceptance criteria for final disposal. Therefore, even historical conditioned waste in a bituminous or concrete matrix, which doesn’t meet current acceptance criteria for conditioned waste can be retreated in a plasma facility, resulting in a conditioned product that does meet these criteria.

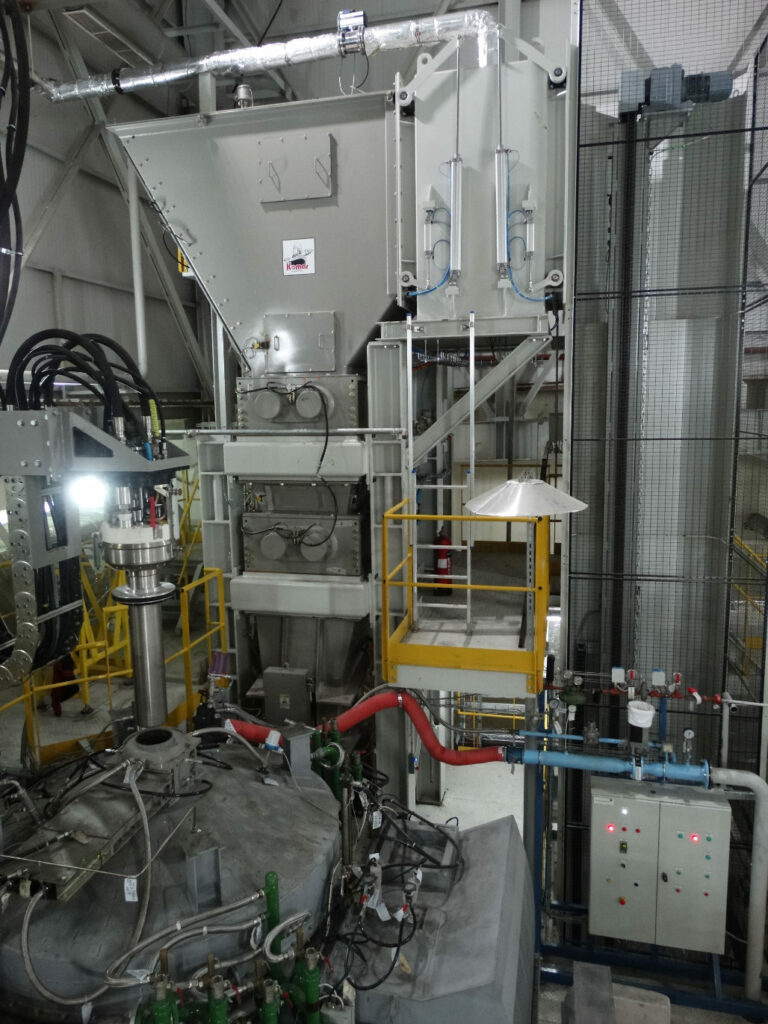

Belgoprocess provided start-up services for the first full-scale plasma installation at the ZWILAG facility in Switzerland, which started operations in 2004. Two campaigns per year of about 10 weeks are organized to treat the stored waste. During each campaign, approximately 500 drums or 100 tons are treated.

The Joint Venture IBERDROLA – BELGOPROCESS, with MONTAIR as a main subcontractor, has built a plasma melting facility for the Kozloduy Nuclear Power Plant in Bulgaria. The facility, which started operations mid 2018, can process 250 tons per year, spread over 40 operational weeks.

In 2018-2020, Belgoprocess performed a feasibility study for the treatment of Belgian radioactive waste in a plasma installation. This study was performed with the support of the Energietransitiefonds (Energy Transition Fund) of the FPS Economy.

In 2018-2020, Belgoprocess performed a feasibility study for the treatment of Belgian radioactive waste in a plasma installation. This study was performed with the support of the Energietransitiefonds (Energy Transition Fund) of the FPS Economy.

Today, Belgoprocess is a process provider for various plasma studies across the world.

In 2018-2020, Belgoprocess performed a feasibility study for the treatment of Belgian radioactive waste in a plasma installation. This study was performed with the support of the Energietransitiefonds (Energy Transition Fund) of the FPS Economy.

In 2018-2020, Belgoprocess performed a feasibility study for the treatment of Belgian radioactive waste in a plasma installation. This study was performed with the support of the Energietransitiefonds (Energy Transition Fund) of the FPS Economy.